Servicing and Rebuilding a Jaguar XK 6-Cylinder Engine

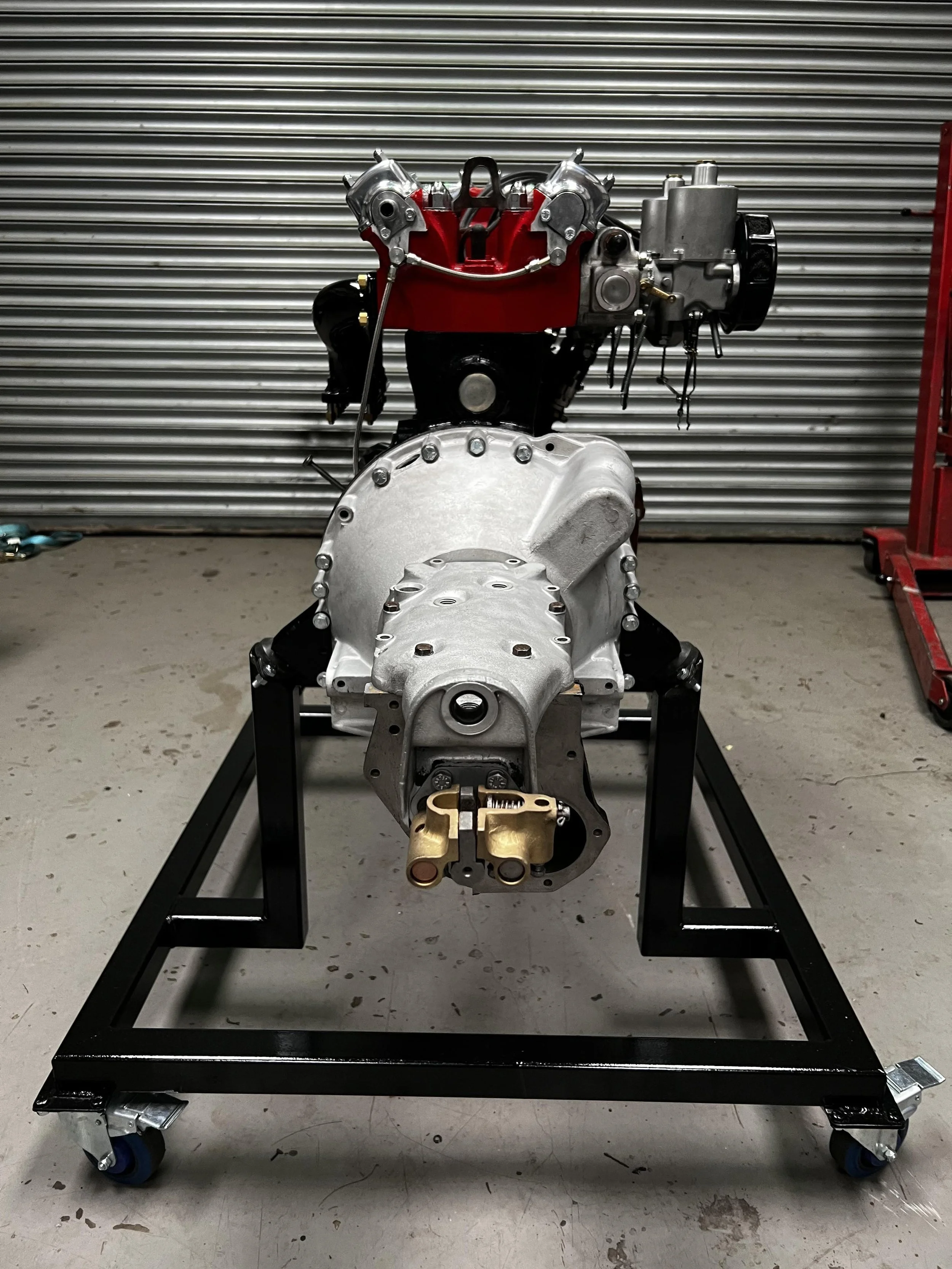

The legendary Jaguar XK 6-cylinder engine is one of the most significant British engines ever built. This engine was introduced in 1948 and was refined over four decades. It has powered everything from the XK120 to the E-Type, MK2 and early XJ models. Although each Jaguar varies widely, the engines themselves share the same fundamental construction, which means the maintenance requirements, service procedures and known failure points are remarkably consistent across all XK engines. With our nearly 6 decades of experience as classic Jaguar restoration specialists, we have the knowledge, expertise and experience to service and rebuild Jaguar XK 6-cylinder engines. This article breaks down what’s involved in servicing an XK engine and the key areas for a full engine rebuild.

The XK engine is robust, but it relies on mechanical precision. Unlike modern engines with hydraulic lifters and electronic ignition, the XK demands manual adjustment, periodic lubrication checks and careful carburettor tuning. Correct servicing prevents most major problems. However, a lack of servicing, especially on engines that see infrequent use, can lead to problems with overheating, low oil pressure, poor running, misfires, hard starting, camshaft wear, excessive tappet noise and poor fuel mixture and imbalance.

One of the most important parts when servicing Jaguar XK engines is checking and adjusting the valve clearances and checking the camshaft health. All XK engines use solid tappets, which means valve clearances must be adjusted manually using shims. Whilst servicing the top-end of the engine, you need to check the valve clearances with feeler gauges, and the condition of the cam lobes for pitting, scoring and wear. In addition, you should check the cam follower condition, oil delivery to the camshafts, the condition and tension of the upper timing chain and the cam cover gaskets and half-moon seals. Clearances can tighten over time due to valve seat wear, and tight clearances prevent valves from closing fully. This can lead to hard starting, loss of compression, burnt valves and misfires when hot. Some common signs that you’re experiencing issues with the top-end are a ticking/tapping noise, rough idle, and backfiring on overrun. As well as low compression on one or more cylinders and visible cam scoring. A properly serviced top end restores smooth idle, performance and reliability.

Some of the other key areas to inspect whilst servicing an XK engine are the timing chains, tensioners and guides. The XK engine uses both upper and lower timing chains. With age, these chains stretch, and the tensioners wear. Whilst conducting a service, you need to listen for any chain rattle on start-up and overrun. Additionally, you should inspect the upper chain guides for cracking, check the tensioner operation and assess the sprocket and any intermediate gear wear. Some symptoms of timing wear are a rattle at idle, poor ignition timing stability, a lack of low-end torque or an erratic idle. Significant chain wear usually means an engine rebuild or partial stripdown is approaching.

Another area to inspect whilst servicing a Jaguar XK engine is the ignition system. The XK 6-cylinder engine was originally fitted with a mechanical ignition and requires periodic adjustment to run correctly. Whilst servicing the ignition, you should replace or adjust the contact breaker points, check the condenser (if it’s still fitted), inspect and clean the distributor cap and ensure the rotor arm is in good condition. Additionally, you should test the vacuum advance unit, check the mechanical advance weights for movement and set the ignition timing at idle and verify advance. Some common faults with the ignition include misfires under load, difficulties cold starting, pinking from over-advanced timing and timing scatter from worn distributor shafts.

In addition, whilst servicing an XK 6-cylinder engine, you should check the carburettor and fuel delivery. The Jaguar XK engines use SU or Stromberg carburettors, which require regular adjustment to maintain the correct mixture and balance. Whilst servicing the engine’s carburettors and fuel delivery, you should check and top up the dashpot oil, balance the carburettors and throttle linkages, set the idle speed and mixture and inspect the needles, jets and diaphragms. It is also important to check the float height, inspect for air leaks at mounts and spindles and check the fuel pump output and fuel hose condition. Poor carburettor tuning and fuel delivery can lead to issues with lean running from vacuum leaks or incorrect mixture, over-rich running from worn needles or incorrect float height or an unstable idle from worn throttle spindles. Correct carburettor setup is essential, particularly after engine work or rebuilds.

Furthermore, overheating is one of the most common causes of serious damage to XK engines; in particular, it can cause cylinder head warping and head gasket failure. This highlights the importance of a well-functioning cooling system. The radiator condition should be checked, and the coolant flow, along with testing the thermostat operation and inspecting the water pump bearings and seals. In addition, you should also check the fan operation, along with the quality of the hoses, clamps and coolant, and flush the system to remove any silt buildup. Any overheating should be investigated immediately. Some common issues include internally restricted radiators, silt blocking the water jackets, poor coolant circulation and sticking thermostats or trapped air.

To ensure your Jaguar XK engine has longevity and remains in good condition, good oil pressure is critical, particularly for the camshaft and timing chain lubrication. Some important steps for servicing the oil pressure and lubrication system include replacing the oil and filter, checking the hot idle oil pressure, inspecting for oil leaks and sump pickup for sludge and confirming that oil is getting delivered to the camshaft. Some warning signs include low oil pressure when hot, persistent oil leaks and excessive camshaft wear.

Whilst servicing your XK 6-cylinder engine, you can complete a compression and leakdown test to provide a clear picture of the overall engine health. This test can help determine whether further servicing or a rebuild is required. Your XK engine may require rebuilding when multiple issues are present, including low hot oil pressure, excessive crankcase blow-by, persistent overheating and camshaft or timing chain wear. As well as bore wear or piston noise, repeated head gasket failure or valve clearances are beyond adjustment limits.

If you were looking to get your Jaguar XK 6-cylinder engine rebuilt, a full engine rebuild would include a cylinder head overhaul of the valves, guides, seats, seals and machining, along with a rebored block with new pistons and rings and a reground crankshaft with new bearings. Some other adjustments include rebuilt connecting rods, new timing chain, guides and tensioners, rebuilt or replaced oil pump, cooling system refurbishment and rebuilt carburettors and ignition system. Furthermore, to ensure longevity, a rebuilt XK engine requires careful running-in. Therefore, it’s important to avoid sustained high loads, vary engine speed, monitor oil pressure and coolant temperature and conduct early oil and filter changes.

If you are looking to get your Jaguar XK 6-cylinder engine serviced or rebuilt, please contact us with confidence! Call us on 0115 926 2266 or email us at info@thorntonrestorations.com. You can also click the link below to find out more about servicing a 6-cylinder E-Type.